Product Review: PlumBest Spray Weld

![]()

For decades PVC pipe and fittings have been joined using a can of solvent applying the solvent using a dauber. For conversation sake, the term used, is “gluing pipe”. When in fact it is solvent joining pipe. Historically required by code is the 2 step method of applying purple primer, then the solvent, then pushing the pipe into the fitting. To insure primer was used, inspectors could see the purple color of the primer in addition to the “glue.” This has caused the colors purple and blue to be associated with a better solvent joining method. It is only a color added, not an active ingredient that is purple or blue, or even red.

The can and dauber method has been a messy and wasteful process. In addition, cans having lids that allow the solvent to evaporate cause a very short shelf life for the solvent. The result is when you need your can of solvent, it’s gotten thick and un useable or dried up to be hard as a rock. As well as dry up, the cans could leak the primer or solvent into the box of fittings the can was tossed into and ruin the whole box. Now you have ruined the fittings and have no solvent when you got to the job site. Now more loss, being time to go get another can. While this scenario has not been 100% of the time, this clearly describes the downside of the can/dauber method.

Now Spray Weld, makes a can, but it’s a spray can sealed to a point of a listed 2 yr. shelf life! In addition, I have had several cans in my shop for over 6 yrs. One of them periodically used for minor repairs that is still working to this day. This can has not dried up, spilled, gotten stringy, nor has the nozzle plugged up. This can of spray has both the primer and the solvent mixed together. It has been explained to me how the mixing together the primer and solvent works and that is as good as the can method it’s self.

This product has a listing by IAPMO as approved for joining PVC water pipe, and by NSF as safe for potable water pipe. It is recommended that anyone joining PVC pipe be advised of the proper methods of this process. One detail is ambient temperature is an issue, (60°F or warmer is advised), another is water pressure in the pipe. Yet another issue, is curing time before charging the pipe with water. I strongly recommend the methods suggested in the PlumBest Spray Weld instructions for use. In addition, the chamfering of the pipe end before applying solvent as the code requires.

The more I study this product the more I like it. This is one reason I give this product a 5 star rating. For homeowners that seldom join PVC pipe it is even more of an advantage to have a sealed spray can. Once the technique of intermittently tapping the spray nozzle to apply the solvent is mastered this seems to be cleaner than the older drippy dauber method. If the pipe is larger, like 2” or more, this spray method is not only neater, but faster.

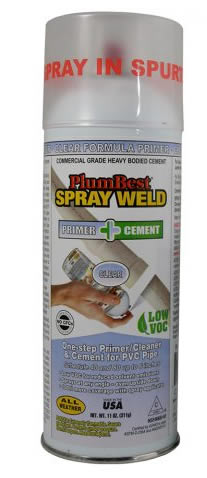

The product comes in both purple and clear varieties of both 4.5 and 11 ounce spray cans.

Personally I would use the clear solvent/primer Spray Weld product before the blue/purple spray because it looks neater. But, one needs to see where the spray has contacted the pipe and if all the surface needing solvent, has solvent.

Manufacturer's website for PlumBest Spray Weld http://www.jonesstephens.com/?s=spray+weld