Water Heating

Water heaters are essential and living with a broken one quickly becomes inconvenient at the very least. They're also a constant energy user so chosing the right one is important for both reliability and efficiency.

Here are some guides to choosing a water heater from Jen Reviews

How to Choose a Water Heater, According to Science

Hot Water Recirculation Systems

Save over 10,000 gallons of water a year and get faster hot water to every fixture.

Save over 10,000 gallons of water a year and get faster hot water to every fixture.

See how to install it yourself with simple tools! more...

Heat Pump Water Heaters

![]() Learn about the most efficient water heaters available.

Learn about the most efficient water heaters available.

Imagine heating your water using only the heat from the air in the room! That's what a heat-pump water heater does. more...

Learn about tankless water heaters!

A tankless water heater save water, energy, and money (plus you don't run out of hot H2 0)!

Listen to what a tankless water heater is, and its advantages and disadvantages.

Listen to what a tankless water heater is, and its advantages and disadvantages.

Listen in..

Water Heater Rocket

Is water heater safety important? You BET it is!

You should be very critical of your water heater and examine it as closely. A damaged water heater could cause danger to members of your household. It can also be costly especially when the water heater's damage is significant. It's better to be always on the safe side and make sure that our water heaters are in good condition in order to avoid accidents.

Watch this short "Mythbusters" video that clearly demonstrates how powerful a poorly rigged water heater can be. For this demonstration the water heater's thermostat and pressure relief valve have failed, no thermal expansion tank is installed, and steam pressure inside the tank builds up turning the water heater into a rocket and flys up to 150 feet in the air!

But before a water heater goes ballistic, all that pressure takes a toll on the home's plumbing. When the water heater heats a large quantity of water (say, after a shower) the water expands slightly, and that expansion has to go somewhere, which can significantly increasing the pressure,! The symptoms may be a toilet fill valve (ballcock valve) running on its own, or "unrelated" leaks in various places (e.g., faucets). A thermal expansion tank can absorbe the expansion pressure changes and prevent the damage (and costly plumbing repair bills).

Glossary for Water Heating

[an error occurred while processing this directive]Frequently UNasked Questions

- What is anti-scald?

Scalding is a burn injury, often caused by hot water. First and second degree burns can result from hot tap water. At least on source states that tap water scalds are the second most common cause of severe burn injuries among people of all ages. Scalding is like age, in that before you know it, it’s too late! The hospitals are always treating a water scald person or even dozens of them. Scalding is rarely intentional! No one intends to have an accident. However, unlike age, scalding is preventable.

Temperatures are dangerous in relation to time of exposure. Some people slip in the shower knocking the temperature lever to full hot! As they are getting up and out 3 seconds pass and bada-boom, pain and an ambulance ride off to the burn center. Slipping into a tub of water that’s too hot can require hospitalization. Babies and invalids are especially at risk.

Simply turning down the water heater is not a sufficient method of limiting the water temperature. Even though you may set the hot water heater’s thermostat to 120°, the water leaving the tank could be over 150°! This is due to the large temperature differences that can exist within the hot water tank itself and the fact that the tank’s thermostat is at the bottom of the tank where the cold water is injected.

Lowering the temperature of the available hot water is the safest way to avoid scalding. To do this, ASSE 1016 approved mixing valves can be installed at each plumbing fixture that uses hot water. (ASSE is the world's oldest and largest professional safety organization; they list and approve the valves). These valves limit the temperature of the hot water available to the fixture and won’t allow water hotter than 110 or 120°, depending on which model you have. 110° at a lavatory basin and shower is safe. This mixing valve is out of the way and in wall or cabinet, and is often installed below the sink. Some models of these valves are set to a fixed temperature and some are adjustable within limits. The absolute best way to have all temperatures the way you want/need them is point-of-use tempering, as custom setting is always possible at each point of use.

Another method of limiting water temperature is with an ASSE 1017 valve. These approved valves serve multiple fixtures, and are often put at the water heater, taking cold and adding it to “super heated” water in tank. (This also has the advantage of essentially expanding the hot water tank’s capacity). If this type is used and the farthest fixture isn’t too cold, that’s the way to go, but 70 ft. of pipe without insulation gets cold really fast, unless it starts out scalding hot! So, for the farthest fixture to get sufficiently hot water, the closer fixtures may end up getting super-heated water (over 130°). In addition, there is also significant heat loss (about 8°) from the time the water leaves the shower head, until it hits the user. Therefore, careful consideration is needed before this type of valve is considered the best and safest installation. You don’t want to have a fancy valve put in only to have it result in lukewarm showers!

A little background on types of hot/cold water mixing valves: Pressure balance and thermostatic valves are different. Thermostatic valves set a specific temperature, and as long as that temperature water is possible, you get it. The ASSE 1016 and 1017 valves mentioned above are thermostatic. Thermostatic valves are factory calibrated and temperature accurate.

Pressure balance valves don’t know the water temperature, but only the relative pressure of the hot and cold supplies. These valves dynamically compensate for a change in flow (pressure) of the cold vs. hot water supply. If cold flow decreases, the pressure balance spool slides over, equalizing the hot flow to match it. This prevents the shower temperature from going up 30° when someone flushes the toilet. However, these valves do not try to compensate for the temperature changes that are not due to pressure changes. So, as the hot water tank is used and the hot water supply gets cooler, you have to turn up the hot side manually. At any temperature, a pressure balance valve won’t let any water thru if only one side is on. This valve requires flow on both sides (hot and cold). Pressure balance valves also have a limiter but it is mechanical, not thermostatic. This limiter is set by the installer to limit the travel of the handle so users can't turn the water up to over 110° or 120. However, if the water heater is subsequently turned up, the calibration done by the installer is no longer valid.

Some shower valves themselves are thermostatic. The desired water temperature is marked right on the valve, and they are calibrated by the installer, and accurate. Some models also have a stop limiter that required pushing a release button to go beyond a certain temperature. These valves do not require an ASSE 1016 valve behind them, as they provide the scald protection themselves.

There are also anti-scald shower heads. These shut off in a second if water hotter than 120° or so goes thru the head. This head has a quick-acting thermal valve in it that shuts off all flow if the threshold temperature is reached.

Whether you are designing new, or retrofitting an existing building, have children, elderly, or disabled persons in the building, and how the fixtures are laid out in relation to the water heater, all play a part in determining what is the best device for your situation. Give me a call and ask me what I can do for you, in order to to provide the hot water you want and the anti-scald safety you need.

- Why does a water heater go bad?

The following refers to tank type water heaters.

- Water heater tanks in California have an average life of 8.5 yrs. (last I checked) until it is replaced, for any reason. The steel tank of a water heater has a protective glass lining on the inside. This lining has pinholes in it (microscopic ones) when it comes from the factory (though Bradford white brand claims the least). Water eventually is able to seep through the pin holes and corrode the steel tank. As the corrosion develops, eventually you will have a leak, and that leak cannot be fixed.

Different things speed up this process. First, expansion and contraction from the temperature change the water in the heater cycles through (from the cold water inlet temperature to the target heated temperature is usually over a 60° F difference, often more). The temperature increase also causes a pressure increase in the tank. As the tank bulges from the pressure increase, the glass lining cracks, allowing water to penetrate the glass lining, which leads to corrosion of the surrounding steel tank, resulting in a leak.

Undersized water heaters, especially in cold climates exacerbate the problem. With cold water inlet temperatures as low as 35°, and target hot water temperature as high as 140°, the thermal expansion cycle can be significant, especially if ALL the heated water is pushed out buy cold water (as would be the case for an undersized tank) . The tank goes from 140° to 35° in a short time repeatedly (daily). A water heater that is not undersized is not drawn cold at every use, or even daily. Solar pre-heat systems will reduce this temperature swing often allowing a tank to last 15 plus years! The solar pre heat also makes for an easier job for the home’s non-solar water heater due to less run time of heating elements/burners.

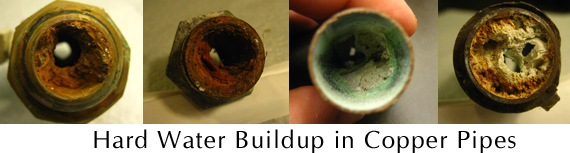

- The quality of the water can affect the speed of the process; corrosive water speeds it up and non-corrosive water slows it down. It is said by some that hard water deposits can fill the cracks in glass lining protecting the tank walls; however hard water creates its own problems with hard water deposits. Softened water avoids most of the hard water deposit problem, but, the softened water has enough salt to cause corrosion through the pin holes. So, other than having a very natural water supply, there is no perfect answer here, you’re dammed if you do, and dammed if you don’t .The picture below illustrates how hard water deposits can form, even within the pipes themselves.

One device to help slow or prevent the corrosive effects of the water is an anode rod installed in the tank. Sometimes called a sacrificial anode rod, the theory is that the corrosive elements attack the rod and avoid the walls of the tank itself. I think the anode rod in the tank is a good thing. Some say if you replace this slowly dissolving rod that you can keep the corrosion attacking the rod and not the tank. Some commercial installations, and wise homeowners, routinely replace this rod every 2-3 years which allows the tank to last over 20 years. Replacement is not necessarily easy but the replacement part is relatively inexpensive, and can likely pay for itself in extended tank life. Manufactures distribute water heaters regionally, with the rod’s composition tailored for the corrosive elements common to that region (different regions have different corrosive elements) Sometimes a smell in the hot water is present from this dissolving reaction of the rod. A change to a different type of rod is needed to stop the smell.

- Another reason tanks fail is that hard water deposits fall to bottom of the tank where a layer of several inches of the material builds up. This build up of sediment in the bottom of the tank forms a thick layer of insulating rock, which prevents the burner below the tank from heating the water in the tank efficiently. A thumping and bumping may be heard coming from the tank. This is caused by the deposits popping off the walls of the tank. In electric water heaters, the hard water compounds also stick to the elements, just like hard water sticks to a tea kettle bottom.

Once it accumulates, the hard water particulate is almost impossible to clean out, as just draining the tank isn’t effective because the sediment on the inside of the tank more than just a few inches away from the drain will not be drawn out the drain cock. However, the sediment build up can be prevented to a certain degree. Self cleaning dip tubes, through which the cold water enters the tank, attempt to reduce the buildup. (Bradford White brand calls this a Hydro-jet feature.) The self-cleaning dip tubes are manufactured with holes in them that cause the water in the tank to spin, putting the hard water particulates into suspension, so that they are drawn out with the hot water and do not accumulate in the tank bottom. This feature, while not 100% effective, is worth the minimal extra expense.

- Corrosive action from the outside of the tank can also occur in the flu of a gas water heater. This corrosion happens when oxidizers in the air react during while the burner is on in the flu/combustion chamber. Among the sources of oxidizers in the air that can add to corrosion in the flu are bleach, fertilizers, soaps, cleaners, insecticides, and other chemicals. An interesting note is that, gas water heaters are not allowed in hair salons (due to the airborne chemicals often found there) unless they are installed in a different room and the water heater gets its air from outside for combustion.

- Water heater tanks in California have an average life of 8.5 yrs. (last I checked) until it is replaced, for any reason. The steel tank of a water heater has a protective glass lining on the inside. This lining has pinholes in it (microscopic ones) when it comes from the factory (though Bradford white brand claims the least). Water eventually is able to seep through the pin holes and corrode the steel tank. As the corrosion develops, eventually you will have a leak, and that leak cannot be fixed.

- How can I get more hot water out of my water heater tank?

Both gas and electric tanks have a thermostat, which can be turned up. However, it is dangerous to make hot water over 120° (due to increased scalding risk, and it’s tough on the tank – see Why a water heater goes bad), but it’s also bad to keep water at a temperature that encourages legionnaires bacteria to grow (legionella thrives at 120°.). This is a “quagmire” to quote Martha Stewart; liability exists either way.

In hospital and laboratory environments they make hot water 180° and use an ASSE approved mixing valve on the outlet of the tank. These adjustable mixing valves add cold water to the hot water on its way out to building. Mixing the temperature down like we do at a shower valve, when showering. This adding of cold water extends the hot water available to the building from that water heater tank. ASSE 1017 & 1016 standards are professional standards ratings and qualified plumbing contractors are needed to add these valves. The hot water producing capability of a common household 50 gallon water heater can be expanded significantly. The device is a couple hundred dollars and needs pipe reconfiguring to install, so total cost is in the neighborhood of $500 (depending on the individual installation). Compare that to installing a larger water heater that may cost 3-4 times as much – and may not even be practical - due to size, location, and venting issues.

A thermal expansion tank is also often added to the task, for absorption of the water volume expansion due to temperature increase. Failure to absorb thermal expansion can result in high pressure leaks, burst pipes causing bodily injury, water heater damage, etc. More energy can be consumed and the life of the water heater can be shortened from the hotter settings. Using a mixing valve is also an improvement to the water temperature stability ( the temperature doesn’t fluctuate as much) and an expansion tank stabilizes the delivery pressure. Both devices require an engineered application. Sorry, this is not a do-it-yourself project.

Another configuration uses the ASSE1016 standard products, which allows the piping in the building to be hot (more than 120°) and a mixing valve goes at each fixture using hot water. An advantage of this method is that each separate hot water outlet can be set to a different temperature. Sometimes that’s a better application of plumbing engineering. A partial application of this is in place now, as anti-scald shower valves are mandated by all codes.

Give me a call, and find out what would work best for you!

- Tell me about tank type water heaters (proper size, venting, BTU ratings, types).

Sizing

The first thing to realize is water heating is “sized” by first hour delivery at a certain degree of rise. The rise is the change in temperature required between the cold water inlet and the desired hot water outlet temperature. In cold climates the inlet temperature can be significantly lower than in warm climates, and the water heater has to be properly selected to handle the difference.

For example: A water heater being fed 80 ° water and heating it to 120° needs a 40° rise. Depending on make & model, a 50 gallon water heater will produce about 70 to 80 gallons of 120° water in the first hour. If you need a 90° rise from the same unit (e.g., 50° water heated to 140°), you will get about 40 gallons the first hour.

In southern California, I size water heaters to a nominal 60° rise for a year round average, figuring on a required rise of 50 to 60° with an output temperature of about 120° and a constant year round hot water usage.

BTU Rating

The BTU (British Thermal Units) rating refers to the amount of heat the burner puts out. Residential Tank type heaters have, at best, between 32,000 and 40,000 BTU. That BTU rating is also the approximate limit of the exhaust vent that is installed in most homes (3”), and the highest BTU I have seen in a residential unit.

My experience is a regular 40 gallon tank will work for 2 people if they don’t need to fill a large tub in the winter or supply for guests at anytime. 50 gallons is a more appropriate family size.

Rheem made a “50/50” that had 50 gallon tank and 50,000 BTU. It put out about 90 gallons the first hour. However, this unit was not approved for installation in California.

Smaller Tank Size/Higher BTU Water Heaters

Bradford White has really great water heaters in 20, 30, 40, and 50 gallon sizes with high BTU Ratings (about 100,000 BTU) which are approved for residential installations. The higher BTU rating requires a 4” vent (most existing houses have a 3” vent). For new construction the Bradford White is the absolute best for a tank type!

The smaller Bradford-White tank capacities and higher BTU rating produce water hotter than what is needed at the faucet. This smaller tank has a mixing valve factory installed at the outlet and mixes cold water with the heated water from the tank. Delivery is a consistent 120° ( a safe temperature), and because the hot water delivered to the faucet is only partially supplied by the hot water tank itself, the first hour capacity of the tank is greatly increased. (You’ll see that other articles on this page refer to this mixing valve as an ASSE 1017 mixing valve.)

I will refer to this setup as a cross between tankless and tank type water heaters. It’s really the best of both worlds. Some locations can’t provide the 200,000 BTU of gas required for a tankless water heater, so Bradford White unit is perfect because it needs about 100,000 BTU. Further, this Bradford White can be vented with regular type B venting. (More on venting shortly, but this is the most common venting in use.) Tankless water heaters need special direct venting, and that’s expensive.

While I am praising Bradford White, I will say the tank they make is very well glazed inside; the glass lining is second to none. “Hydrojet” is a self cleaning feature they have, and the new code requirement for FVIR (Flammable Vapor Ignition Resistant - having a sealed burner chamber that prevents igniting flammable vapors in the water heater area) is serviceable on Bradford White (but not by all manufacturers). The efficiency ratings on Bradford White tanks is tops.

Indirect Fired Water Heaters

Another option is a water heater with no burners at all, called an indirect fired water heater. This type of water heater has a heat exchanger coil inside that carries hot water from another source – such as the home’s boiler. In this example, the water heater acts as another zone on the home’s heating system and uses the water heating power of the home’s boiler to provide hot water. No venting is required for the water heater (since it has no burner), yet is retains the efficiency of gas, and the high BTU power of the home’s boiler. As an example, a 40 gallon Bradford White indirect fired water heater has a rating of 260 gallons of hot water the first hour, assuming a 157,000 BTU output from the heat source (but not all home boilers will have that much capacity, so the output would be accordingly less).

Venting

The proper venting is critical. Improper venting is life threatening.

There are a few basic types of venting used for residential water heaters. The proper type of venting depends, in part, on the efficiency of the appliance (water heater, furnace, or combination), and the pressure of the appliance’s exhaust gases, which is a characteristic of the appliance’s design.

The higher efficiency appliances produce a cooler exhaust. This sounds great, but the cooler, exhaust does not rise out of the vent as easily as hotter exhaust gasses. The cooler exhaust gasses also form condensation more easily, especially in cooler climates. The condensate is acidic and corrosive, and therefore requires the proper venting material to ensure that leaks don’t form and infiltrate the home. If the exhaust gasses vent into a masonry chimney, installation of high efficiency appliances may require lining the chimney, as the condensate can destroy the mortar between the bricks and lead to the collapse of the chimney.

Some systems have negative pressure exhaust systems, where the hot exhaust gasses are drawn out of the building by their own buoyancy; this is the most common tank type water heater design. Others (especially higher efficiency appliances) have positive pressure exhaust that must be pushed or drawn out with a fan, and must also be properly sealed. Some installations (though not typically water heaters) may also require a condensation drain in the exhaust system. The air-tightness and venting of the house can also affect exhaust venting requirements. This is to ensure that a negative pressure inside the house does not cause outside air to be drawn in through the exhaust vent resulting in the actual exhaust entering the home, a dangerous condition known as “backdrafting.”.

Direct venting is a term that is used for a gas water heater that has a sealed combustion system and gets its air for combustion thru a second passage in the vent system. Direct venting can be used for both tankless and tank-type water heaters.

Type B venting is double wall vent having an insulating effect and twist-lock or snap-lock connections. It is required by code for common gas burning appliances and has been for decades. Type B venting is useable on appliances with lower efficiencies and negative pressure exhaust systems. It is the most common gas water heater vent in use. Type B type venting is not useable for direct vent type or tankless water heaters.

Category 3 venting is for systems with a positive pressure exhaust, but operating at a temperature where condensation is not usually an issue. It is typically made from stainless steel. Noritz tankless water heaters utilize category 3 venting.

Category 4 venting is used for high efficiency–positive exhaust pressure heating systems, where condensation in the flue is most likely to occur.

PVC or CPVC may also be used for some installations with low temperature, positive pressure exhaust.

All venting systems use special connectors, flashings, and installation requirements. Some can be vented horizontally out the side of the building, some cannot. Each appliance has its own requirements and no one vent type works for them all. Check with the manufacturer, who will require the vent system that works properly with each unit, and do not vary from their requirements. It would not just be a code violation; it would also be dangerous, if not fatal. I don’t recommend DIY for most people in water heating, gas work, or venting. I do recommend understanding the difference in the systems so one can decide how to hire someone to get the work done properly.