Frequently UNasked Questions

Here are some questions that most consumers don't ask often enough. I want to keep you well informed about what's best for you and your situation for the long term.

I hope you enjoy them,

Greg

Plumbing Service

- Why you don't always get a licensed plumber when you call one, and why it matters.

A story:

Acme Plumbing (a fictitious company)

Joe Homeowner (a fictitious person)

John - employee (a fictitious person)

Free (the estimate on the phone)Joe Homeowner calls Acme Plumbing. A nice lady answer the phone and says "Acme Plumbing, home of the free estimate, license plumber for over 20 years."

Joe Homeowner says, "I need you to send a plumber over hear ASAP."

The nice lady at Acme says "within 60 minutes, sir!" and Joe responds "Great!"

So, John shows up (he isn't really a fictitious person, he's a person working for the owner of Acme Plumbing.) John, has been doing this for two years now and has been riding along with another guy who has been working at Acme for 5 years. Neither of them are licensed plumbers, nor trained to any standard set anywhere. They sometimes do a good job, and sometimes not!

John fixes the leak for an agreed amount and all is fine, until another leak causes Joe Homeowner to call and hire John again. John and Joe were "chummy" before and are still on OK terms now, because it's a different faucet leaking now and Joe figures John's last job worked (plus he seemed clean, honest, etc.), so he will use him again .

This repeats itself five more times in six months, until Joe Homeowner is getting poor. John now tells him he needs a pressure regulator and that will cost $500. Joe nearly has a cow, and says "my regulator isn't leaking it looks fine, it’s all dry” , “I just want what work you have done to not leak”, “Don’t try to sell me more”, John explains: “your regulator is letting pressure thru so high its causing your faucets to drip, it’s not leaking externally, its leaking internally, and needs replacing “, Joe Homeowner replies, “If that’s what is wrong, why didn’t you fix that first?"

But John didn't take a pressure reading when he first went to fix the faucets, so he didn't know the pressure was so high (over 150 psi in this case!). He didn't diagnose the cause of the leaking faucets to begin with, he waited until there were so many occurances of it, he couldn't ignore it any longer (plus he made more money with the additional service calls). He thought his work would not leak because it was new. The flow of water didn't reveal the high pressure, because the regulator was restricting the flow, but not the pressure. Once the faucet opened up the "push" was lost. Trained plumbers should know this.

The pint being made is understanding system dynamics, thermal expansion, and other techie stuff is an important element of plumbing knowledge. Being a professional plumber is more than parts replacement and ability to solder, and “roto rooter” ( a misused term). Employees might be educated, even ethical, but not always. Employees are just that, they are not plumbing contractors. Further, all Licensed contractors aren’t all educated beyond passing a test given by State Licensing Board - which does not require continued education at all. So, 40 years can pass with multiple product developments and advancements, yet you're assured very little as to if the “plumber” knows how to, or even anything about the better advancements.

I (Greg Chick - Ramona's Plumber) DO get continuing education. I also serve as a “subject matter expert” to the State Licensing Board and have consulted with them to this issue and they are working on it…. Some day….it might change , but for now this is my story and I am sticking to it. My goal is to do away with the need to “call a plumber” to fix a poorly designed/installed fixture, or poorly applied plumbing product. It should be done right the first time!

Well done plumbing can and should last much longer and perform better than it commonly does today!

Water pressure and flow are my specialty, and too often the cause of your problem. As you can see in this story example that the leak is often just the symptom, not the true problem.

The good news is that I.A.P.M.O. link and the Green Plumbers USA have entered into an agreement to train “plumbers.” IAPMO happens to be the source of State Lic. Board Training material and test questions. Green Plumbers USA is a fairly new organization, but I will say that when/if Green plumbers USA gets done the Certification they offer will be worth more than the current State Lic. (that is our goal).

- The Cost of Plumbing Service: Myths, Fears, and Facts

When you go out to eat for breakfast, do you ask the restaurant manager how much he paid for the eggs, potatoes, and bacon on your plate?

Of course not, though everyone expects the cost of the food to be marked up by a huge margin.

If you took a taxi to your breakfast, youíd fully expect to pay a trip charge as well as a tip.

But when it comes to plumbing, consumers sometimes have unfair expectations. They think, “If I knew how to solder, I could fix plumbing problems myself.”

They ask, “That faucet only costs $40 at the store, why are you charging so much to install it?” More goes into soldering pipes or installing a faucet than goes into most breakfasts.

Besides the charge for his expertise, you need to factor in that a plumber has the expense of a plumbing truck, tools, and parts. Not to mention a plumber is expected to have liability insurance and be trained to prevent or correct any potential problems that could occur during a service call.

As a consumer, I can understand the fear of overpaying. However, the next time that you hire a plumber, try to consider all the expenses that go into plumbing work. That, or start bugging restaurant managers – you know, to be fair.

Product Quality and Cost

- Why some products cost more.

For starters, how much zinc/"potmetal" is in a product makes a large difference in cost and quality. Even brass (primarily a mixture of copper and zinc) is not all cast the same. The best brass is not even cast, but milled from a brass rod or bar stock.

California Proposition 65 required that lead can no longer be a component in brass plumbing fixtures. Lead was a small, but important, component in the brass that was used to "hold the brass together". As a result, components are too often made of poor quality materials that don't hold up, and faucets begin to leak as a result. Other examples include:

- Thin tubular spouts corrode, and don't last.

- Thin castings don't hold to specifications.

- Poor qualtiy materials that warp and pit, causeing o-ring seals to lose their seal.

The weight of a faucet or valve can be a sign of quality as it indicates how much metal is in the product. For example, triple chrome plating is better than thin single plating. You can feel the difference. See Faucet Finishes.

High quality brands such as Grohe's Lady Lux kitchen faucets will function better and last longer than products made of poorer quality materails. They do cost more, but they may actually be a better value in the long term.

Unfortunately, the high quality brands may not be readily available to the consumer at the home improvement store.

Give me a call, and let me help you pick out the best choice for your situation. I also have access to the high quality products that you may not be able to find in a retail outlet.

- Why some cost more and aren't better.

Some products have a name and a slogan that has been expensively sold to you in advertising. Advertising dollars that costs you the consumer. As a result, you end up paying signifcant amounts just to have the latest finish style, even though the finish may not even be real metal. For example, some stainless steel finishes are not even real metal, but a printed-on image instead.

You will find various styles of plumbing fistures like colonial, neo deco, and antique look. These styles sell the products, but the quality behind them is, too often lacking. Also, the quality of the warranties they come with is too often, not very good.

A high quality brand such as Grohe and their Lady Lux line of kitchen faucets come in stainless steel finish and the body of the faucet is actually stainless steel. The metal is finished for the particular style, to produce not just the look, but to actually be what it claims or suggests it is. High quality brands will function better and last longer too.

Unfortunately, the high quality brands may not be readily available to the consumer at the home improvement store. Give me a call, and let me help you pick out the best choice for your situation. I also have access to the high quality products that you may not be able to find in a retail outlet.

- Why design matters (or form vs. function).

When I talk about design, I'm not talking about the appearance of a faucet, instead I'm talking about the thought and planning that went into the water supply system that connects to it. For example, if design isn't right when a high flow shower system is installed (e.g., small size supply pipe), then the $5,000 shower "power wash" won't have enough to flow. If piping layout isn't good, drains can repeatedly get blockages. If a landscape patio "fire ring" is limited by the ½" stub out intended for a small BBQ, the flames will be smaller than the design.

Good design can get higher grade products for less money! A good design will be less trouble than a poor design.

Some examples:

- Single hole lavatory faucets are a good design. They provide only one hole to cut, and clean around, and only one to install, no tubes to connect below the basin, less to leak, and cost less too! Wide spread lavatory faucets require three holes in the counter top or sink basin and are expensive. Wall mount are even better, as wet hands will drip into the basin and not on the area at the base of the faucet. However, this is a design-in feature, not a faucet-only choice.

- Distribution of hot water (multiple water heaters) is better than long distances to run and wait for hot water.

- Design of the laundry at the highest point in the house is a good design, as it uses the volume of the laundry water to flush out other waste (that has been reduced in volume due to plumbing code requirements). This keeps the entire drain system healthy.

These are just a few simple examples of the hundreds of things to consider. Let me help you design and lay out your project, and give you some suggestions on good, efficient, and cost effective design choices that will enhance the pleasure you get out of your home systems.

General Plumbing issues

- Top 10 Home Plumbing Myths That Cost You Money.

Everybody knows it: it’s ‘conventional wisdom,’ passed down generation to generation. It applies to anything and everything and unfortunately, in many cases, it’s oversimplified or just plain wrong.

The conventional wisdom in plumbing is no different; there are many myths. Freshen your drain with lemon? Run water with the garbage disposal? Good ideas? Find out as we explore the top 10 plumbing myths that cost you money!

Myth #1: Putting Lemons in Your Disposal to Make It Smell Fresh Is a Good Idea

When life gives you lemons, don’t put them down your disposal! You might succeed in briefly creating a fresher aroma, but the citric acid from lemons corrodes the metal inside your disposal.

The Better Alternative:

Use ice to polish your disposal up inside, which works just like a rock tumbler polishing rocks; itís noisy, but it works. Power wash the scum causing the odor from the drain without ruining your disposal.

Myth #2: ďIn TankĒ Cleaners Will Keep Your Toilet Sparkling and Smelling Like Roses

Spending money on “in tank” cleaners marketed to make your chores easier and decrease the time you spend scrubbing your toilet is one cost you can cut.

These products bleach smelly build-up white, but donít get rid of it. Eventually, the build-up can ruin your toilet.

The Better Alternative:

Use vinegar down the overflow tube. Vinegar removes smelly build-up that can damage the flow of your toilet for a fraction of the cost.

Myth #3: Lifetime Warranties on Bad Products Are Really Useful

When you buy something cheap and it breaks, donít expect to get it replaced with the latest and greatest product on the market.

What you buy is what youíre stuck with. Plus, youíll be spending time and money to keep reinstalling it.

The Better Alternative:

Buy good quality products the first time around and avoid trading in junk for junk.

Myth #4: Running Water While Using the Garbage Disposal Helps the Waste Travel Smoothly

Sure, it seems like the perfect combo: letting the faucet run while using the garbage disposal to help wash waste down the drain. Itís something weíve all done.

And inevitably, weíve all had to reach our hands down the drain to unblock whatever leftovers got jammed in the pipes.

Following waste with water doesnít help if the blockage has already happened before the water shows up.

The Better Alternative:

Fill the sink basin with a 4:1 ratio of water to waste so that the waste is separated and flows with ease down the drain.

Myth #5: As Long as Stuff Is Going Down the Drain, Everything Is Working Correctly

Out of sight, out of mind doesnít really apply to the plumbing world.

Even if you canít see it, food like pasta and rice will bloat in pipes causing clogs, blocking the passage for other waste to peacefully pass through the pipes.

Without the proper amount of water to rinse it down, waste builds up in the pipes and makes drainage inefficient.

The Better Alternative:

Prevent blockage and clogging problems by using sinks, toilets, and showers correctly. Make sure to fill basins with water before draining. For showers, place a hair screen in the drain to reduce the human hairballs that rival anything your cat coughs up.

Myth #6: Water Pressure Regulators Are Always Dependable

Water pressure regulators do give important information about water pressure, but donít place all of your trust in the readings they provide.

The Better Alternative:

Personally check your water pressure! Doing so can save you a ton of hassle and money.

How? Well, high water pressure is a major cause of floods, leaks, and that annoying sound your toilet makes as it continuously runs to relieve pressure.

Myth #7: Water and Soap on Bathroom Fixtures Makes Them Just as Sparkly and Clean as Your Hands

You wash your hands at the sink and when you turn off the faucet, you leave a bit of soapy water on it. No big deal, right? Wrong!

Water and soap cause faucets and fixtures to corrode, making them peel and bubble.

The Better Alternative:

Wipe the fixtures off after use. This takes an extra second, but it will help prevent your fixtures from corroding.

This will also protect your lifetime warranties on products, which are void when soap has rotted the finish.

Myth #8: Users Manuals Are Only For People Who Donít Know What They Are Doing

User manuals arenít just full of fancy labeled pictures and lists of parts. They actually contain some useful information as well.

While they may not be the most entertaining read in the world, they can save you money and time in the long run.

The Better Alternative:

Read the manual. Twice. User manuals contain information on warranties and proper usage that will increase the lifespan of the product.

Myth #9: Plumbing Fixtures Are Low Maintenance

Ignoring plumbing fixtures because they are hard as stone and cold as steel is not only mean, itís detrimental to their performance.

Lack of use allows a p-trap to evaporate, allowing dangerous sewer gas to smell up the house.

If an electric water heater sits unused, it can create highly explosive hydrogen gas. In this case, you definitely want less bang for your buck.

The Better Alternative:

Donít let your plumbing fixtures and equipment sit for long periods of time. Use them periodically to ensure health risks arenít created.

The time it takes to turn them on every once in awhile could save you a fortune if you prevent your home from exploding.

Myth #10: Every Plumber Knows Exactly What to Do and How to Do It

Just because a plumber holds that title doesnít mean that they are educated in their field and licensed.

Every plumber has opportunities to get continued plumbing education, certificates, and special cards to install some products.

If a plumber installs something poorly or chooses the wrong fixture, youíll just have to spend more calling another plumber.

The Better Alternative:

Use state boards and the BBB to ensure the plumber you are hiring is well qualified and well educated in the field.

- Why copper leaks.

Copper piping usually leaks because it is not installed properly, or due to water or soil corrosion issues.

Some water is corrosive to copper and after time pin holes happen in the copper walls of the pipe. Some soils below a slab are corrosive. Corrosive soil eats holes through the outside wall of the pipe. Concrete and copper do not mix! Copper piping below slabs has been a multi-million dollar repair business. Copper piping should never be embedded directly in the slab.

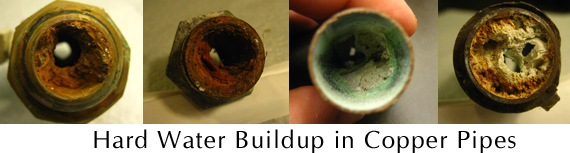

In this photo, the copper pipe failed from the inside, corroded completely through, and formed a leak.

Solder joints have failed from various reasons: Lead in older systems and poor workmanship in lead-free joints of today's lead-free solder. It hasn't been easy for plumber employees to solder quick and completely using the mandated fluxes and solders that don't work as well as the older ones did. In the photo below a very small leak is indicated at the joint of the pipe and valve fitting, by the presence of the hard water deposits left as the leaking water evaporated.

Velocity due to undersized copper piping causes leaks and the price of copper keeps the sizes too small. If copper is not properly reamed when cut, turbulence and leaks are caused at the joint. Reaming takes time and discipline - which some employees don't have.

Presence of tiny air bubbles in water is hard on copper as are poor strapping and loose pipe. J-hooks pierce pipe, and expansion and compaction wear on the pipe also.

[Hide text] - Why brand names have "those trendy finishes" and cost $19-$900.

Trendy finishes sell faucets, and lots of them. That is how volume name brand faucets are sold in a wide market. This requires selling to the lowest price availability and to the people willing to pay. Marketing names do studies to find what buyers want, then mix and match the prices with the finishes and shapes (colonial, tuscan, etc.). After the most wanted finish is determined, they only put that finish on the "top of the line" series.

All of this marketing cost money, and lots of it. This money comes from what the manufacturers do not put into the product.

- Why does a noise occur when I use my water?

Any sound is a result of vibrations, the frequency and intensity of the vibration determines what sound is generated. Water “whizzes” past and thru sharp edges, elbows, and rough pipe walls, and thru valves having small passages. The turbulence in the water causes the vibrations and makes noise. Just like “white water” (no, not a Bill Clinton scandal), but the turbulence of flow. Vibration from turbulence resonates through the pipe and surrounding materials, and that makes sound. When pipes touch the wall, the wall board acts like a speaker! The pipe travels through the building making noise any opportunity it has (touching wall board, studs, or anything that conducts vibration).

The minimum pipe size used (as per code), strapped as per code, isn’t always done according to the code’s intent (or sometimes not done at all), and banging occurs. Isolation of piping requires skill, tools, isolators, and testing. The optimum is not sought after by many, compounded by the fact that lots of buildings move as they age, and the slight shift may allow the pipe to have direct wood contact.

Sometimes water velocities increase, and a noise develops, long after code has been complied with! For example, a pressure regulator “all of a sudden”- wears out from water erosion and chlorine (after 20 years - is that all of a sudden?). The failed regulator lets more pressure through, and bada-boom - pressure makes velocity, and that makes noise!

If a plumbing fixture is added after the original piping is sized, you can have an undersized pipe branch making noise.

Copper itself is not the quietest pipe material! Conduction of sound from a faucet noise can travel a long way. Valve noise can travel from the pressure regulator at the home’s inlet to the upstairs master bedroom bath!

Poor grade valves in retail grade “priced-to-sell” fixtures can be noisy. It is the size and shape of the casting and valves in the faucet itself that can make the noise.

Shut off “stops” under sinks are also a very noisy problem. The velocity inside is very high and washers often get loose and chatter when water whizzes past at 30 ft. per second (proper velocity is 1.5 ft. to. to 10 ft. per second, NOT 20 or 30 ft. per sec.)

Old multi-turn valves can get a loose washer causing a shuttering or rapid banging when used. Whistling and humming are also caused by high velocity water vibrating the plumbing. See my “Plumbing stories” for a real twist on that!

Pipe banging is caused by the sudden stoppage of water within the pipes. Fast moving water caries a good amount of inertia. When a valve closes suddenly (and ¼ turn valves can close very quickly), the energy of the water coming to a sudden stop causes a “water hammer.”

Noise from underground landscaping irrigation can travel into the building! Often sprinklers in the yard are not pressure regulated (so that the system can get away with fewer control valves). I find 20 ft. per sec. very common in landscape sprinklers; however, code specifies the max flow rate is 10 ft. per sec. for PVC. That high velocity, vibration, and water hammer effect can all cause: you guessed it, noise!

Waste water can also cause noises, and is governed by the same physics.

If you have noisy pipes, give me a call. It may be a symptom of a more serious issue. Early diagnosis can prevent more serious and expensive damage that could result if left unchecked.

Toilets

- Why some toilets don't flush well.

First, lets start off by explaining how a toilet is supposed to work. The passage leading from the bottom of the bowl to the drain pipe has a vertical bend it. Like all household drains this maintains some water in the base of it to prevent gasses from the septic system from seeping into the house (this is the trap below all other drains). Before the waste water goes into the waste piping, the water must go up over this vertical bend. If the vertical bend in the pipe (the trap) can be quickly filled when the toilet is flushed, a siphon will be formed and draw (suck) the contents of the bowl into the drain system. To adequately start this siphon action, the initial water flow from the bowl must be of sufficient speed and volume to completely fill the trap and the passage and initiate the flow of the bowl contents via the siphon action.

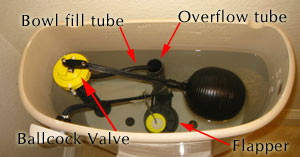

When you push a toilet tank lever, the lever lifts a flapper on the flush valve which releases the water contents of the tank into the bowl, via the siphon jet (at the bottom of the bowl) and the flush ring (the rim of the toilet with the little holes in it). The siphon jet initiates the flow of water from the bowl into and through the trap and starts the siphon action . The continued flow of water into the bowl from maintains the level of water in the bowl to support the siphon until all the waste contents can be emptied. In top performing toilets, this happens in less than 2 seconds.

There are other bowl designs that don't use the siphon jet, but the basic operation is the same and this design is the most common.

By the way... The spinning of water in the bowl during the flush sequence is actually counter productive to the flush action.

Toilets may not flush well for a number of reasons.

- Toilets are cast out of many pieces of ceramic (china), these pieces fit together and then are glazed and fired to look like one smooth pice. However, if the inside the passageway of the toilet is not smooth (often because it is not glazed), the siphonic action (i.e., the flush) is weak, and the flush does not evacuate the contents of the bowl completely. The resolution is to have a quality High Efficiency Toilet (HET). The design and manufacture of these toilet ensures a smooth passage way for a strong siphon.

The transfer of the water from the tank to the bowl can be impaired by mineral buildup in the flush ring and siphon jet. The slower the transfer the poorer the flush. The mineral build up and reduces the initial flow of water into the trap, resulting in a poor siphon. The resolution is to quickly poor about a quart white vinegar down the overflow tube (located in the toilet tank). Let the vinegar work for a minimum of about 2 hours (preferably overnight) before flushing. It may help to first remove the small 1/4 inch bowl fill tube that comes from the ballcock and to the overflow tube. The vinegar dissolves the calcium (hard water build up) in the flush ring and the siphon jet, allowing the toilet to once again work as designed. You may need to repeat the process several times. Annual treatment could be necessary.

The transfer of the water from the tank to the bowl can be impaired by mineral buildup in the flush ring and siphon jet. The slower the transfer the poorer the flush. The mineral build up and reduces the initial flow of water into the trap, resulting in a poor siphon. The resolution is to quickly poor about a quart white vinegar down the overflow tube (located in the toilet tank). Let the vinegar work for a minimum of about 2 hours (preferably overnight) before flushing. It may help to first remove the small 1/4 inch bowl fill tube that comes from the ballcock and to the overflow tube. The vinegar dissolves the calcium (hard water build up) in the flush ring and the siphon jet, allowing the toilet to once again work as designed. You may need to repeat the process several times. Annual treatment could be necessary.

See my video on this subject The bowl fill tube no longer discharges into the overflow tube. If the bowl fill tube does not empty into the overflow tube, the bowl will not refill after flush. Starting out with a low bowl water level will result in a poor flush. The resolution is to reconnect the bowl fill tube to the overflow with a clip, to keep the bowl fill tube in place. It's also important is to ensure the bowl fill tube does not extend too far down into the overflow tube (1/4 inch) or constant cycle of tank-siphon loss and refill could occur.

The bowl fill tube no longer discharges into the overflow tube. If the bowl fill tube does not empty into the overflow tube, the bowl will not refill after flush. Starting out with a low bowl water level will result in a poor flush. The resolution is to reconnect the bowl fill tube to the overflow with a clip, to keep the bowl fill tube in place. It's also important is to ensure the bowl fill tube does not extend too far down into the overflow tube (1/4 inch) or constant cycle of tank-siphon loss and refill could occur.

The chain from the handle to the flapper valve is not properly adjusted. If the chain is too long, the flapper valve does not lift up enough to move to the fully open position (where it normally floats until the tank water level drops enough to allow the flapper to close). If the chain is too short, the flapper valve may be prevented from fully closing or from opening enough. The resolution is to adjust the chain length so that the slack in the chain is 1 or two links (no more, no less). A loose flush handle can be the cause of inconsistent adjustment of the chain, resulting in the above problems, and is a common cause.

The chain from the handle to the flapper valve is not properly adjusted. If the chain is too long, the flapper valve does not lift up enough to move to the fully open position (where it normally floats until the tank water level drops enough to allow the flapper to close). If the chain is too short, the flapper valve may be prevented from fully closing or from opening enough. The resolution is to adjust the chain length so that the slack in the chain is 1 or two links (no more, no less). A loose flush handle can be the cause of inconsistent adjustment of the chain, resulting in the above problems, and is a common cause.

- The flapper valve is binding on something and cannot operate properly. The valve may be colliding with toilet bowl cleaner, or other objects in the tank. A similar problem arises from installing the wrong flapper when replacing one, or installing it improperly (Many flappers are designed to fit different types of flush valves, some flappers may require cutting some pieces away for proper installation - Read the Instructions!).

- The bowl trap has an object in it, such as a toy, toothbrush, shaver, paper towels or other object that has fallen into the bowl and hung up inside the trap (which is only about 2 inches wide with sharp turns). The resolution is to use closet auger (toilet auger). Available for about $30 at a hardware store, or for rent at the local rental outlet.

- Why does a toilet leak?

Let's first define what a toilet leak is, and differentiate it from your toilet running (or filling) constantly. We'll consider a leak to be water on the floor (water is leaking out of the toilet).

If you have a leak (water on the floor), it could come from:

- A leak at the tank to bowl spud (the flush valve gasket) or a leak at the tank to bowl bolts (which each have a rubber gasket). In either case, replace both the bolts and the spud. Both readily available at the hardware store.

- A loose ballcock nut. This is located on the outside bottom of the tank, and would cause water to flow down the outside of the supply line and drip. It may first appear to be a supply line leak.

- The supply tube nut is loose (at the base of the tank).

- The supply valve is leaking.

- The bowl wax seal no longer seals. This is actually rarely the problem and always caused by some other issue such as a loose toilet, sagging floor, or improper wax ring installation in the first place.

- The bowl fill tube had come out of the overflow tube and is now spraying out between the tank lid and the tank, running down the side of the tank onto the floor. Open the lid of the tank, flush the toilet, and see where that little 1/4 inch tube is aiming.

- A cracked tank. Rare, but a possibility.

If your toilet is running, and the constant filling is on and off, then it could be one of several things:

If your toilet is running, and the constant filling is on and off, then it could be one of several things:- Flapper valve warped or not closing.

- Bowl fill tube siphoning (the bowl fill tube is too far down into the overflow tube in the tank, resulting in a constant cycle of partially draining and filling the tank)

If the constant filling is non-stop, then it could be:

The ballcock mechanism (the float in the tank) could be catching or hanging up on something.

The ballcock mechanism (the float in the tank) could be catching or hanging up on something.

- The ballcock valve has sediment in it an needs to be cleaned out. See my video on how to do this. View it on YouTube

- The ball cock valve has failed and should be replaced.

- Why don't you use a plunger to clear a toilet clog?

You may be surprised to know that I don't even have a plunger among my plumbing tools! While this has been used by many people for many years, using it for a toilet is not a very good idea.

You may be surprised to know that I don't even have a plunger among my plumbing tools! While this has been used by many people for many years, using it for a toilet is not a very good idea. Here's why:

- It could push the blockage even further down the pipe. If the blockage was due to something that won't dissolve like a comb, now you've really got problems. You may have to open up the floor or slab to get at the blockage or hire someone with an expensive camera outfit to go in and find it.

- The pressure exerted by the plunger could blow out the wax seal, without you knowing it. Even with the wax seal compromised, it may work fine...for a while. But a subsequent blockage would allow water (sewage) to leak out of the damaged seal and into your floor, under your tile, and making a general nasty mess of things.

- "Toilet matter" could be pushed up into the siphon jet of the toilet (that's the little hole that water comes out to help the toilet start to flush). Water is supposed to come out of that hole, and nothing should go in. There's no good way to clean that out once anything gets up in there, so that could cause long term problems for that toilet.

- It can splash! You certainly don't want any "toilet matter" splashing around, on to your face, clothes and the room itself. Not only is it unsightly, and nasty to even think about, it is a genuine honest-to-goodness health hazard!

So, what should you use to clear a toilet clog? A closet auger. They are the right tool for the job and affordable too. It's what I use. See my do-it-yourself page for a YouTube video on exactly how to use one.

Septic Systems

- Septic Tank Maintenance: Why Pump it Out?

I want you to understand that a septic tank is a living system. Just as live enzymes and bacteria digest our food in our bodies, these same enzymes and bacteria (“life”) continue to live and eat, while emitting gas (a byproduct of the digestion). This digestion takes place on the way to the tank, inside the tank, and even after the tank as the effluent flows into the leach field. However, adding excessive amounts of bleach, anti-bacterial soap, or caustic drain cleaners can kill these organisms. Harsh chemicals do not belong in septic systems. If the natural “life” is reduced, the digestion will decrease and sludge will fill the septic tank, along with Fats, Oils, and Grease (FOG). This will need pumping out!

A septic tank does not need to be pumped because it gets full. Once a septic tank reaches its capacity – which doesn’t take long (about 1100 gallons on average), it is normally full all the time! Solids fall to the bottom of the tank, where the organisms in the tank continue to digest it (and emit methane gas - which is vented to the atmosphere). Once at capacity, spillage then flows out pipes into the leach field, where it percolates down into the ground.

I know of Septic Systems that are 40 years old and never been Pumped! These are healthy self-sustaining systems. The reason that tanks are pumped when a house sells, is not to get rid of the contents, but to allow an inspection of the tank for decay or damage (this is required in California).

To maintain system health, I strongly recommend adding liquid and fresh live enzymes into septic systems regularly. Enzymes will also keep the FOG from collecting in drain pipes in the building, saving you a blocked drain. Powered or dry Enzymes have a shorter shelf life, so be sure to check for freshness to ensure they will actually work.

Just as water flows out of the tank system into the leach field, if the leach field is saturated (such as during heavy rains), the water can actually flow back into the system – obviously causing trouble when you try to add more waste to it. Rain water Infiltration is a product of poor grading, design, and installation. Septic pumpers work around the clock when rains are heavy. But the pumping only provides temporary relief until the leach field can be functional again.

Please don’t flush pharmaceuticals down the drain (whether you have a septic tank or are hooked up to a sewer system), they end up in our drinking water! Nature doesn’t digest this stuff. Point of use responsibility is only way this world is going to stay clean. The stories of frogs changing sex is not “Earth people paranoia.” This is very real, but - another story.

Water Heaters

- Why does a water heater go bad?

The following refers to tank type water heaters.

- Water heater tanks in California have an average life of 8.5 yrs. (last I checked) until it is replaced, for any reason. The steel tank of a water heater has a protective glass lining on the inside. This lining has pinholes in it (microscopic ones) when it comes from the factory (though Bradford white brand claims the least). Water eventually is able to seep through the pin holes and corrode the steel tank. As the corrosion develops, eventually you will have a leak, and that leak cannot be fixed.

Different things speed up this process. First, expansion and contraction from the temperature change the water in the heater cycles through (from the cold water inlet temperature to the target heated temperature is usually over a 60° F difference, often more). The temperature increase also causes a pressure increase in the tank. As the tank bulges from the pressure increase, the glass lining cracks, allowing water to penetrate the glass lining, which leads to corrosion of the surrounding steel tank, resulting in a leak.

Undersized water heaters, especially in cold climates exacerbate the problem. With cold water inlet temperatures as low as 35°, and target hot water temperature as high as 140°, the thermal expansion cycle can be significant, especially if ALL the heated water is pushed out buy cold water (as would be the case for an undersized tank) . The tank goes from 140° to 35° in a short time repeatedly (daily). A water heater that is not undersized is not drawn cold at every use, or even daily. Solar pre-heat systems will reduce this temperature swing often allowing a tank to last 15 plus years! The solar pre heat also makes for an easier job for the home’s non-solar water heater due to less run time of heating elements/burners.

- The quality of the water can affect the speed of the process; corrosive water speeds it up and non-corrosive water slows it down. It is said by some that hard water deposits can fill the cracks in glass lining protecting the tank walls; however hard water creates its own problems with hard water deposits. Softened water avoids most of the hard water deposit problem, but, the softened water has enough salt to cause corrosion through the pin holes. So, other than having a very natural water supply, there is no perfect answer here, you’re dammed if you do, and dammed if you don’t .The picture below illustrates how hard water deposits can form, even within the pipes themselves.

One device to help slow or prevent the corrosive effects of the water is an anode rod installed in the tank. Sometimes called a sacrificial anode rod, the theory is that the corrosive elements attack the rod and avoid the walls of the tank itself. I think the anode rod in the tank is a good thing. Some say if you replace this slowly dissolving rod that you can keep the corrosion attacking the rod and not the tank. Some commercial installations, and wise homeowners, routinely replace this rod every 2-3 years which allows the tank to last over 20 years. Replacement is not necessarily easy but the replacement part is relatively inexpensive, and can likely pay for itself in extended tank life. Manufactures distribute water heaters regionally, with the rod’s composition tailored for the corrosive elements common to that region (different regions have different corrosive elements) Sometimes a smell in the hot water is present from this dissolving reaction of the rod. A change to a different type of rod is needed to stop the smell.

- Another reason tanks fail is that hard water deposits fall to bottom of the tank where a layer of several inches of the material builds up. This build up of sediment in the bottom of the tank forms a thick layer of insulating rock, which prevents the burner below the tank from heating the water in the tank efficiently. A thumping and bumping may be heard coming from the tank. This is caused by the deposits popping off the walls of the tank. In electric water heaters, the hard water compounds also stick to the elements, just like hard water sticks to a tea kettle bottom.

Once it accumulates, the hard water particulate is almost impossible to clean out, as just draining the tank isn’t effective because the sediment on the inside of the tank more than just a few inches away from the drain will not be drawn out the drain cock. However, the sediment build up can be prevented to a certain degree. Self cleaning dip tubes, through which the cold water enters the tank, attempt to reduce the buildup. (Bradford White brand calls this a Hydro-jet feature.) The self-cleaning dip tubes are manufactured with holes in them that cause the water in the tank to spin, putting the hard water particulates into suspension, so that they are drawn out with the hot water and do not accumulate in the tank bottom. This feature, while not 100% effective, is worth the minimal extra expense.

- Corrosive action from the outside of the tank can also occur in the flu of a gas water heater. This corrosion happens when oxidizers in the air react during while the burner is on in the flu/combustion chamber. Among the sources of oxidizers in the air that can add to corrosion in the flu are bleach, fertilizers, soaps, cleaners, insecticides, and other chemicals. An interesting note is that, gas water heaters are not allowed in hair salons (due to the airborne chemicals often found there) unless they are installed in a different room and the water heater gets its air from outside for combustion.

- Water heater tanks in California have an average life of 8.5 yrs. (last I checked) until it is replaced, for any reason. The steel tank of a water heater has a protective glass lining on the inside. This lining has pinholes in it (microscopic ones) when it comes from the factory (though Bradford white brand claims the least). Water eventually is able to seep through the pin holes and corrode the steel tank. As the corrosion develops, eventually you will have a leak, and that leak cannot be fixed.

- How can I get more hot water out of my water heater tank?

Both gas and electric tanks have a thermostat, which can be turned up. However, it is dangerous to make hot water over 120° (due to increased scalding risk, and it’s tough on the tank – see Why a water heater goes bad), but it’s also bad to keep water at a temperature that encourages legionnaires bacteria to grow (legionella thrives at 120°.). This is a “quagmire” to quote Martha Stewart; liability exists either way.

In hospital and laboratory environments they make hot water 180° and use an ASSE approved mixing valve on the outlet of the tank. These adjustable mixing valves add cold water to the hot water on its way out to building. Mixing the temperature down like we do at a shower valve, when showering. This adding of cold water extends the hot water available to the building from that water heater tank. ASSE 1017 & 1016 standards are professional standards ratings and qualified plumbing contractors are needed to add these valves. The hot water producing capability of a common household 50 gallon water heater can be expanded significantly. The device is a couple hundred dollars and needs pipe reconfiguring to install, so total cost is in the neighborhood of $500 (depending on the individual installation). Compare that to installing a larger water heater that may cost 3-4 times as much – and may not even be practical - due to size, location, and venting issues.

A thermal expansion tank is also often added to the task, for absorption of the water volume expansion due to temperature increase. Failure to absorb thermal expansion can result in high pressure leaks, burst pipes causing bodily injury, water heater damage, etc. More energy can be consumed and the life of the water heater can be shortened from the hotter settings. Using a mixing valve is also an improvement to the water temperature stability ( the temperature doesn’t fluctuate as much) and an expansion tank stabilizes the delivery pressure. Both devices require an engineered application. Sorry, this is not a do-it-yourself project.

Another configuration uses the ASSE1016 standard products, which allows the piping in the building to be hot (more than 120°) and a mixing valve goes at each fixture using hot water. An advantage of this method is that each separate hot water outlet can be set to a different temperature. Sometimes that’s a better application of plumbing engineering. A partial application of this is in place now, as anti-scald shower valves are mandated by all codes.

Give me a call, and find out what would work best for you!

- Tell me about tank type water heaters.

Sizing

The first thing to realize is water heating is “sized” by first hour delivery at a certain degree of rise. The rise is the change in temperature required between the cold water inlet and the desired hot water outlet temperature. In cold climates the inlet temperature can be significantly lower than in warm climates, and the water heater has to be properly selected to handle the difference.

For example: A water heater being fed 80 ° water and heating it to 120° needs a 40° rise. Depending on make & model, a 50 gallon water heater will produce about 70 to 80 gallons of 120° water in the first hour. If you need a 90° rise from the same unit (e.g., 50° water heated to 140°), you will get about 40 gallons the first hour.

In southern California, I size water heaters to a nominal 60° rise for a year round average, figuring on a required rise of 50 to 60° with an output temperature of about 120° and a constant year round hot water usage.

BTU Rating

The BTU (British Thermal Units) rating refers to the amount of heat the burner puts out. Residential Tank type heaters have, at best, between 32,000 and 40,000 BTU. That BTU rating is also the approximate limit of the exhaust vent that is installed in most homes (3”), and the highest BTU I have seen in a residential unit.

My experience is a regular 40 gallon tank will work for 2 people if they don’t need to fill a large tub in the winter or supply for guests at anytime. 50 gallons is a more appropriate family size.

Rheem made a “50/50” that had 50 gallon tank and 50,000 BTU. It put out about 90 gallons the first hour. However, this unit was not approved for installation in California.

Smaller Tank Size/Higher BTU Water Heaters

Bradford White has really great water heaters in 20, 30, 40, and 50 gallon sizes with high BTU Ratings (about 100,000 BTU) which are approved for residential installations. The higher BTU rating requires a 4” vent (most existing houses have a 3” vent). For new construction the Bradford White is the absolute best for a tank type!

The smaller Bradford-White tank capacities and higher BTU rating produce water hotter than what is needed at the faucet. This smaller tank has a mixing valve factory installed at the outlet and mixes cold water with the heated water from the tank. Delivery is a consistent 120° ( a safe temperature), and because the hot water delivered to the faucet is only partially supplied by the hot water tank itself, the first hour capacity of the tank is greatly increased. (You’ll see that other articles on this page refer to this mixing valve as an ASSE 1017 mixing valve.)

I will refer to this setup as a cross between tankless and tank type water heaters. It’s really the best of both worlds. Some locations can’t provide the 200,000 BTU of gas required for a tankless water heater, so Bradford White unit is perfect because it needs about 100,000 BTU. Further, this Bradford White can be vented with regular type B venting. (More on venting shortly, but this is the most common venting in use.) Tankless water heaters need special direct venting, and that’s expensive.

While I am praising Bradford White, I will say the tank they make is very well glazed inside; the glass lining is second to none. “Hydrojet” is a self cleaning feature they have, and the new code requirement for FVIR (Flammable Vapor Ignition Resistant - having a sealed burner chamber that prevents igniting flammable vapors in the water heater area) is serviceable on Bradford White (but not by all manufacturers). The efficiency ratings on Bradford White tanks is tops.

Indirect Fired Water Heaters

Another option is a water heater with no burners at all, called an indirect fired water heater. This type of water heater has a heat exchanger coil inside that carries hot water from another source – such as the home’s boiler. In this example, the water heater acts as another zone on the home’s heating system and uses the water heating power of the home’s boiler to provide hot water. No venting is required for the water heater (since it has no burner), yet is retains the efficiency of gas, and the high BTU power of the home’s boiler. As an example, a 40 gallon Bradford White indirect fired water heater has a rating of 260 gallons of hot water the first hour, assuming a 157,000 BTU output from the heat source (but not all home boilers will have that much capacity, so the output would be accordingly less).

Venting

The proper venting is critical. Improper venting is life threatening.

There are a few basic types of venting used for residential water heaters. The proper type of venting depends, in part, on the efficiency of the appliance (water heater, furnace, or combination), and the pressure of the appliance’s exhaust gases, which is a characteristic of the appliance’s design.

The higher efficiency appliances produce a cooler exhaust. This sounds great, but the cooler, exhaust does not rise out of the vent as easily as hotter exhaust gasses. The cooler exhaust gasses also form condensation more easily, especially in cooler climates. The condensate is acidic and corrosive, and therefore requires the proper venting material to ensure that leaks don’t form and infiltrate the home. If the exhaust gasses vent into a masonry chimney, installation of high efficiency appliances may require lining the chimney, as the condensate can destroy the mortar between the bricks and lead to the collapse of the chimney.

Some systems have negative pressure exhaust systems, where the hot exhaust gasses are drawn out of the building by their own buoyancy; this is the most common tank type water heater design. Others (especially higher efficiency appliances) have positive pressure exhaust that must be pushed or drawn out with a fan, and must also be properly sealed. Some installations (though not typically water heaters) may also require a condensation drain in the exhaust system. The air-tightness and venting of the house can also affect exhaust venting requirements. This is to ensure that a negative pressure inside the house does not cause outside air to be drawn in through the exhaust vent resulting in the actual exhaust entering the home, a dangerous condition known as “backdrafting.”.

Direct venting is a term that is used for a gas water heater that has a sealed combustion system and gets its air for combustion thru a second passage in the vent system. Direct venting can be used for both tankless and tank-type water heaters.

Type B venting is double wall vent having an insulating effect and twist-lock or snap-lock connections. It is required by code for common gas burning appliances and has been for decades. Type B venting is useable on appliances with lower efficiencies and negative pressure exhaust systems. It is the most common gas water heater vent in use. Type B type venting is not useable for direct vent type or tankless water heaters.

Category 3 venting is for systems with a positive pressure exhaust, but operating at a temperature where condensation is not usually an issue. It is typically made from stainless steel. Noritz tankless water heaters utilize category 3 venting.

Category 4 venting is used for high efficiency–positive exhaust pressure heating systems, where condensation in the flue is most likely to occur.

PVC or CPVC may also be used for some installations with low temperature, positive pressure exhaust.

All venting systems use special connectors, flashings, and installation requirements. Some can be vented horizontally out the side of the building, some cannot. Each appliance has its own requirements and no one vent type works for them all. Check with the manufacturer, who will require the vent system that works properly with each unit, and do not vary from their requirements. It would not just be a code violation; it would also be dangerous, if not fatal. I don’t recommend DIY for most people in water heating, gas work, or venting. I do recommend understanding the difference in the systems so one can decide how to hire someone to get the work done properly.

- Why does a problem keep coming back?

If a problem keeps coming back, that tells you that you have not fixed the problem, but only the symptoms.

For example, you may fix a leaking pipe, but are you stopping the problem that made the pipe leak in the first place?

One of the most common problems is high water pressure due to a faulty pressure regulator (or no regulator). Over 30% of my business is because of pressure regulators aging and no longer working properly. Pipes and fittings that wont leak at the normal pressure of 80 psi (code requires less than 80psi), might leak at 150 psi, which is not an uncommon street-supply pressure.

High pressure problems may also be caused by thermal expansion. When the temperature of the water heater tank rises, so too can the pressure. This affects both the cold and hot water supply sides in the home. The solution is the installation of a good pressure regulator and an thermal expansion tank.

Faucets

- What is a washerless faucet?

Washerless faucets typically have a 1/4 turn from off to fully on, they do have rubber working surface (but not a washer or compression to seal). To seal they use rubber working surfaces that rotate against each other to allow flow or not. These are generally better than washer type faucet (but not as good as ceramic valves).

- What is a ceramic-valve faucet?

Ceramic-valve faucets typically have a 1/4 turn from off to fully on, and do not have rubber working surfaces or washers. To seal they use a perfectly flat pair of ceramic surfaces that rotate against each other to allow flow or not. These are generally the best.

Design and Consulting

- What is plumbing consulting?

There are four areas of common consulting, (excluding forensic consulting)

- Layout design

- Materials

- Features

- Application

Layout / Design. These considerations are too often limited to the convenience of the architect, builder, or plumber; or due to the loan money available, none of which have the user as the most important factor. Some examples:

- Back to back showers serve the builders and plumbers, not future repairs.

- Water heaters almost always installed in the garage at the end of the house because It is convenient for builders. Putting the water heater next to the furnace in the garage is easy because gas and power and combustion air are already there. This location is often far from the master bedroom, causing a long wait for hot water and also resulting in wasting water. A better layout is two centralized water heaters for large houses. Utility closets having doors and allowances for fresh air are not “convenient,” they cost money.

- Slab construction is good for everyone except the owner! Crawl spaces allow for remodel, repair, and proactive upgrades.

- Pumpless recirculation systems can be done with a basement water heater by using a thermal siphon.

Layout and design needs to be thoughtfully considered for the use, efficiency, and convenience of those that will actually use the building.

Good Design is a very complex layered issue. The builder’s, architect’s, bank’s, or other’s idea of a good design is only from their point of view, and do not necessarily fit the financial limitations and functional needs of the homeowner. The design has a direct effect on the product’s life expectancy and maintenance costs. When a builder/plumber, or other person installs a fixture or “feature” in the system without full knowledge, the misapplication of such “feature” impairs either system quality, efficiency, or life expectancy and too often limits the ability to make repairs possible or without undue expense.

Materials: Some plumbers use brand name fixtures to falsely assure the customer they are getting quality. Mass production fixtures use low grade materials to allow for a low price, and allow money for expensive advertising – telling the customer “they are the best” i.e. “Brand Name”. This branding costs money which does not go into the product. There are over 25 materials used for fixtures.

Proper materials selection doesn’t concentrate on brand name, but places quality, durability, and reliability at the top - in addition to price, all matched to the intended use and user.

Some piping will corrode in 6 months and leak. A waster system will cause corrosion or be worthless in a short time. Some finishes will pit or peel.

Piping materials include ABS, PVC, CPVC, PEX, HDPE, copper, brass, stainless steel, galvanized, black iron, cast iron, and more.

Fixture materials include: cast iron, china, enameled steel, fiberglass, solid composite (quartz, Corian, cultured marble, etc) brass, bronze, plastic, galvanized, copper, glass, and natural stone.

All of these materials do not necessarily mix in form or function, nor do they have the same reaction to heat, water, and other affecting issues that shorten their life or repairability.

I don’t want to say that some materials are bad, but with poor design and installation, materials often fail too soon. Some materials have a lighter “duty rating” (and a lighter price too). When subject to heavy use, corrosive soaps, shifting buildings, temperature differences, etc., they may fail within a short time and need expensive repair.

Features are part of a design and selecting the proper ones is easier with good hindsight (consulting). Knowing what works well and what fails is essential to the future enjoyment of the features. For example:

- A recirculation pump without a timer and aquatstat waste energy and cause leaks in pipes, causing millions in property damage. Noisy pipes can occur from the pump feature.(A timer allows the pump to run only during needed periods of the day, and the aquastat allows the pump to run only after water temp in pipe has cooled down to a set temperature. Energy management controls can pay for themselves and sometimes require good design application.)

- Some people even builders, think threshold-less showers allow water to get onto the floor, Not true.

- Some (even builders) think some high efficiency products cost more – Not true.

- Features that most customers want because they read about them are not fully understood by installers and repairs are quickly needed.

Features are not stand alone items. Features need good application, installation, and sometimes location to work as claimed. There are installations where a tankless water heater won’t work well, or a solar heater wont work well, or ultra-low water use will cause drain blockages.

Application: Consideration must be given to how any fixture installation, and how it will be used and who it will be used by. Often remodels are done to correct poor application of an original design For example:

- Is this a rental, or a luxury home, or one used two times per year?

- Will it be used by a few people or many different people, or people who aren’t responsible?

- Will animals be around?

- ADA needs?

- Code requirement due to special use?

- Are noisy pipes going to be a problem to others?

- Will well water be used?

- Multi-story building?

- Hot or cold climate?.

Misapplications for the above can be a result of how different people use their plumbing.. For example: Some people leave water splashes on the finish of a faucet or soap that could set on the faucet finish for a long enough time to cause pitting or discoloration. Wall mounted faucets allow water to fall into basin and not at base of faucet. Stainless steel (cast body not faux finish) faucets do not corrode (Grohe makes some). Designs having faucets mount to the counter top, and not on the sink basin itself, avoid the “fouling” areas at base of faucet and countertop ledge.

Some products fail when left without use for long periods (a poor choice for a vacation or part-year home).

Building codes don’t effectively cause proper application of fixtures or plumbing.

Mixing of night-use people and day-use people in a multi-family building can be a problem with noisy pipes or any pipes not installed correctly.

Some piping layouts don’t work with some fixtures or products.

Some products having features need “integrating” into a plumbing system, and not just stuck there by the installer.

Some misapplication can cause damage, injury, and repeated problems that don’t have obvious links to the causing product or design.

Conclusion

When I consult for you, I help select the design, materials, features and application that best fits your needs. With foresight based on 30 years worth of hindsight. I know what works and what fails.

- What is water purification/filtering?

Water treatment is a wide subject, and purification can be a misleading word. There is wealth of information available on the internet that I cannot begin to duplicate here. I will say that my information on other plumbing issues here is tops, and almost unparalleled anywhere, but the issue of water is a serious one needing even my two cents on my site. And, I would like to touch on a few subjects to get you started in the right direction.

There are many types and methods of water treatment. The best one for any particular location depends on what the water is to be used for.

Filtering is the process of removing relatively large particles. Filtering methods range from a centrifugal sand separator, or 1/2 micron low flow filter, to expensive compound type filters that use a series of methods. Filters alone do not address dissolved solids (hard water), biological issues (purification), heavy metals, VOC’s (Volatile organic compounds), and more.

Purification generally refers to removing chemicals or biological agents (germs), or both. Activated Carbon filter a common (maybe the simplest and best) form of purification and is also a real cleaner, but does not take out dissolved solids or soften.

Reverse Osmos (RO) addresses almost all issues as they typically include both the filter, and purification steps. Most RO systems have a filter, and activated carbon steps, which removed particles, chlorine and other chemicals, before the water is then passed through the a reverse osmosis membrane which allows almost nothing but water molecules through it. Some RO systems also have Ultra Violate light (UV) to kill live organisms in water.

The downside to RO systems is that the membranes need to be replaced every couple of years (they’re expensive), pre and post filters should be replaced every 6 months. RO water cannot be piped in a copper tube (e.g., from under the sink to the refrigerator). RO is also a slow process and can produce a limited quantity of water per hour. An expansion tank is used that stores the processed water (about 2 gal at any one time), but after a week or so, that water becomes stale and questionable if not used.

How the water will be used is what really determines the proper treatment. You can, of course, overkill, if cost or energy is no object, but realistically conservation is everyone’s concern and education is key to achieve good results in anything.

A whole house treatment system needs to have a higher flow capacity, than say a single glass filler at the refrigerator. And a whole house system need not be as clean as drinking water. Shower water is for some as or more important as drinking water, as some people have a skin problem and chlorine is an irritant from shower water.

New methods of municipal fresh water treatment have changed over the years. Copper pipes are getting pitted from the inside out - due to the water’s contents.

Many people feel that they do not need a filter system, because they buy bottled water. However, bottled water may not be as clean as you think. Some are clean pure than tap water! In fact many bottled water simply dilute the contaminates with RO water, but do not pass all of the product through the RO process. And bottled water does have a shelf life. Since the chlorine has been removed, organisms can grow in it (the list is long).

Recommendation

My recommendation is point-of-use treatment designed for the intended use, whether it is an RO system for drinking at the sink, a carbon filter at the showerhead, or an ion canister for spot free rinse on the car. Shower water (that is chlorine and/or mineral free – for sensitive skin) for does not need to be drinking water quality; softened water which is good for washing, toilets, and laundry is not good for drinking or plants. (Not to be confused with naturally soft water like rainwater {with exceptions}, that is perfect for people and plants.)What is acceptable for a healthy 40 yr old, an immune deficient person, and a child are not necessarily all the same. Children are more susceptible to water-borne diseases than adults.

Point-of-use water treatment is best because you control how the water is treated, shelf life is not an issue, it’s cheaper, and you can ensure that 100% of it goes through the process.

There’s a lot of claims for various water treatment systems. Few are quantified. All claims need to be verified to anyone who cares if they mean anything at all! There are several water quality treatment standards; their meaning to the average consumer may be hard to decipher. Be careful of buzzwords like “pure,” “healthy,” “natural,” and “mountain spring” as they have very little clinical definition and may be more of an indication of the marketing of the water and not its quality.

If you are not happy with the quality of your water, let me help you choose the best system for your particular application.

- What is anti-scald?

Scalding is a burn injury, often caused by hot water. First and second degree burns can result from hot tap water. At least on source states that tap water scalds are the second most common cause of severe burn injuries among people of all ages. Scalding is like age, in that before you know it, it’s too late! The hospitals are always treating a water scald person or even dozens of them. Scalding is rarely intentional! No one intends to have an accident. However, unlike age, scalding is preventable.

Temperatures are dangerous in relation to time of exposure. Some people slip in the shower knocking the temperature lever to full hot! As they are getting up and out 3 seconds pass and bada-boom, pain and an ambulance ride off to the burn center. Slipping into a tub of water that’s too hot can require hospitalization. Babies and invalids are especially at risk.

Simply turning down the water heater is not a sufficient method of limiting the water temperature. Even though you may set the hot water heater’s thermostat to 120°, the water leaving the tank could be over 150°! This is due to the large temperature differences that can exist within the hot water tank itself and the fact that the tank’s thermostat is at the bottom of the tank where the cold water is injected.

Lowering the temperature of the available hot water is the safest way to avoid scalding. To do this, ASSE 1016 approved mixing valves can be installed at each plumbing fixture that uses hot water. (ASSE is the world's oldest and largest professional safety organization; they list and approve the valves). These valves limit the temperature of the hot water available to the fixture and won’t allow water hotter than 110 or 120°, depending on which model you have. 110° at a lavatory basin and shower is safe. This mixing valve is out of the way and in wall or cabinet, and is often installed below the sink. Some models of these valves are set to a fixed temperature and some are adjustable within limits. The absolute best way to have all temperatures the way you want/need them is point-of-use tempering, as custom setting is always possible at each point of use.

Another method of limiting water temperature is with an ASSE 1017 valve. These approved valves serve multiple fixtures, and are often put at the water heater, taking cold and adding it to “super heated” water in tank. (This also has the advantage of essentially expanding the hot water tank’s capacity). If this type is used and the farthest fixture isn’t too cold, that’s the way to go, but 70 ft. of pipe without insulation gets cold really fast, unless it starts out scalding hot! So, for the farthest fixture to get sufficiently hot water, the closer fixtures may end up getting super-heated water (over 130°). In addition, there is also significant heat loss (about 8°) from the time the water leaves the shower head, until it hits the user. Therefore, careful consideration is needed before this type of valve is considered the best and safest installation. You don’t want to have a fancy valve put in only to have it result in lukewarm showers!

A little background on types of hot/cold water mixing valves: Pressure balance and thermostatic valves are different. Thermostatic valves set a specific temperature, and as long as that temperature water is possible, you get it. The ASSE 1016 and 1017 valves mentioned above are thermostatic. Thermostatic valves are factory calibrated and temperature accurate.

Pressure balance valves don’t know the water temperature, but only the relative pressure of the hot and cold supplies. These valves dynamically compensate for a change in flow (pressure) of the cold vs. hot water supply. If cold flow decreases, the pressure balance spool slides over, equalizing the hot flow to match it. This prevents the shower temperature from going up 30° when someone flushes the toilet. However, these valves do not try to compensate for the temperature changes that are not due to pressure changes. So, as the hot water tank is used and the hot water supply gets cooler, you have to turn up the hot side manually. At any temperature, a pressure balance valve won’t let any water thru if only one side is on. This valve requires flow on both sides (hot and cold). Pressure balance valves also have a limiter but it is mechanical, not thermostatic. This limiter is set by the installer to limit the travel of the handle so users can't turn the water up to over 110° or 120. However, if the water heater is subsequently turned up, the calibration done by the installer is no longer valid.

Some shower valves themselves are thermostatic. The desired water temperature is marked right on the valve, and they are calibrated by the installer, and accurate. Some models also have a stop limiter that required pushing a release button to go beyond a certain temperature. These valves do not require an ASSE 1016 valve behind them, as they provide the scald protection themselves.

There are also anti-scald shower heads. These shut off in a second if water hotter than 120° or so goes thru the head. This head has a quick-acting thermal valve in it that shuts off all flow if the threshold temperature is reached.

Whether you are designing new, or retrofitting an existing building, have children, elderly, or disabled persons in the building, and how the fixtures are laid out in relation to the water heater, all play a part in determining what is the best device for your situation. Give me a call and ask me what I can do for you, in order to to provide the hot water you want and the anti-scald safety you need.

Water Conservation

- How can I save water without any of those "water savers" and not even miss it?

First, the old high flow 4 gallons per min. shower heads are not all that good, but new high performance shower heads actually have really strong spray.

The poor-flushing water-hog toilets and the newer poor flushing “water saver toilets” (1.6 gpf) are not as good at flushing the bowl clean as the new 3” flush valves that use only 1.6 gallons per flush. One toilet better than Toto (the brand I recommend most) is the “I can’t find it in San Diego” “Caroma” from Australia. This toilet has a 4" trapway through it! That’s TWICE the size of others! It comes in a dual flush that removes 700 grams (1.5 lbs) of solid waste using only .8 gallons per flush! Most toilets can’t remove 700 grams solid waste using 3.5 to 5 gallons per flush. It’s expensive and hard to find, but a great toilet.

New laundry machines wash better, dry better, are easier to use, and cost less to operate. Consumer Reports has the scoop on the models that the best (not the most popular, but the best functionality/durability, and max performance).

Quality isn’t always found at a big box store, nor is quality often cheaper than the rest. Kind of like music, the best music isn’t on the radio, just the fastest selling commercial stuff that stars get rich on. The difference in music and plumbing is quantifiable in a test of maximum performance, not popular hit. People still try to make plumbing names popular with the name game; I use the max performance test method myself. (I touch on this subject in the answers to several other questions.)

Good design, not brand name, is the answer to proper water use. Proper application of fixtures and following the manufacturer’s recommendations are essential in proper installations. Unfortunately, I don’t see the majority of buildings having this; as a result, repair and replacement are common and repeated. When I say this I mean water heaters fail sooner than necessary, and re-piping a building should not be necessary if it was installed right in the first place.

Pressure in water systems is more variable than most people realize; a good pressure regulator is a must. Water at the meter is usually high pressure, the house often gets the regulator, and the yard gets high pressure (no regulator). This high pressure to the irrigation system causes a mist in the sprinklers allowing 20% to 30% to blow away before it hits the ground. That’s a lot of unnecessary waste, and doesn’t even count run off and evaporation. The national average is 50% of the water through a single family residence’s water meter goes to the YARD! And 30% of that is poof - gone! (That’s 15% of your water bill – for nothing!). Outdoor water waste is costing more money than people realize. While you struggle to make minor improvements to water efficiency on the inside of the house, significant improvements can usually be made in efficiency on the outside of the house without a great deal of effort. A good lawn isn’t one that uses as much water as it takes to be green. A good lawn is one with UNIFORM DISTRUBITION, then enough to keep it green.

Water Auditing is a relatively new process to assess water use. It addresses these issues and is something you’re going to be hearing more about as our water use becomes more expensive and conservation becomes more critical. Water auditing uses catchment cups on a grid pattern over whole lawn area. Analysis of the collected data allows correcting sprinkler head coverage to even out precipitation. Matched Precipitation Rate nozzles are required to achieve this.

For the lawn, maximum depletion of water from the soil BEFORE wilting is needed to save water. Turning on water to satisfy a dry spot is over-watering the rest! Uniform distribution is when an entire area wilts at same time, and then you water for no more than root depth! How deep are YOUR roots? If you don’t know, you’re wasting water! Do you know if your lawn sprinklers have water flowing faster than 10 feet per second? Too high a flow rate can damage valves and blow off heads (wasting water and costing money for repairs due to damage that should not have happened in the first place). Pressure at the base of the sprinkler heads needs to be less than 40 psi. What’s yours? An even lower pressure - 20 to 25 psi is water saving (no mist is produced).

I am trained, qualified, and experienced to help you address these issues, and even perform a water audit, to help you fine tune your system to greatly reduce waste, as well as lower your water bill. I’d also be glad to give you recommendations on the best design features, fixtures, and appliances to fit for your situation. Give me a ring, the phone call is free.

- How can I reuse my waste water?

See my podcast on water reuse. In it I provde a good overview of water reuse around the home. I explain what water reuse is, the different types of resue, what water can and what should not be reused, among other issues.

You can listen on my podcasts page, by clicking the icon below, or on iTunes.

Alternate Water Sources

- Is graywater useable for my lawn?

No. If you treat graywater is is ok to use to spray on a lawn but then it is not graywater anymore, its reclaimed treated water.

- If I am a totally vegan household, can I use my kitchen sink wastewater as I would graywater?

Yes functionally, but code has not accepted any kitchen sink waste as graywater .

- Is the effluent waste water from my water treatment system useable as graywater?

- Can I harvest graywater from my tub or shower on a concrete slab?

- Are there code approved pumps to lift, move and carry waste water over a wall or up a hill to a higher part of the yard?

- Do water treatment systems purify water?

- Are all RO, or Reverse osmosis systems the same?

Yes, is the treatment system is not a salt or magnesium consuming system. And that water may be sprayed on a lawn, unlike graywater.

No, not with out a jackhammer and unreasonable expense. But upstairs tub/showers can be accessed from the ceiling below the fixture and piped to an exterior wall, out and down to the ground. Then to a below grade perforated leach line having a min. 2" of cover even if that cover is mulch.